Process Systems

Biogas is a complex medium that requires careful and constant management to ensure that equipment is protected and continues to carry out its main function of environmental protection. Organics has a wide experience on different process systems from collection, processing, filtration and cleanup of biogas for a variety of applications, to odour control.

Process systems for the control and use of biogas

Activated Air Units

High-rate chemical oxidations systems for variable-source Odour Control. An Activated Air unit consists of a stainless steel cabinet containing wide-mesh UV-catalysts. Ambient air is passed through the unit, from atmosphere without any pre-treatment, and radiated.

Sy-Clone

The Organics stripper/scrubber unit, the Sy-Clone®, is designed for use in a chemical process environment. It is effective by creating a high-impact environment with maximised surface areas, thus facilitating high mass-transfer rates with reduced contact volumes.

Odour Control

Organics possesses a wide range of methods, techniques and technologies that may be employed to identify and remedy specific odorous situations.

Biogas Chillers

The process of extraction of landfill gas for power generation results in the formation of a lot of condensate that can contain a wide range of potentially corrosive elements. If these elements are not removed from the gas flow, they can drop out of the condensate in the engine manifold or charge-cooler; a phenomenon that will eventually result in catastrophic engine failure. To avoid this happening, a chiller will remove condensate prior to entry of the gas to the engine.

H2S Cleaning Equipment

Organics offers bio-scrubber technology for H2S treatment. The main advantage of this approach is that, in most circumstances, costs for chemical-additions are reduced or removed. The bacteria involved in the process are ubiquitous and, as long as correct environmental conditions are maintained, the bacteria will function reliably and predictably in the removal of hydrogen sulphide from gas streams.

some of our reference projects

Fuel Skids Barcelona

Three No. 3,000Nm3/hour fuel skids and a 3,000Nm3/hour enclosed SC flarestack supplied and installed on the El Garraf landfill site in Barcelona. The fuel skids supplied 12 No. 1,064kW engines with landfill gas, The energy was fed into the national grid under a FiT scheme.

Details of the Project

Project Type: Landfill gas to power generation

No. and model of flare stacks: 3 No. 3000,Nm3/h booseter set biogas delivery modules and 1 No. 3,000Nm3/h SC-range enclosed flarestack.

Year of installation: 2006

Availability of fuel skids: >90%

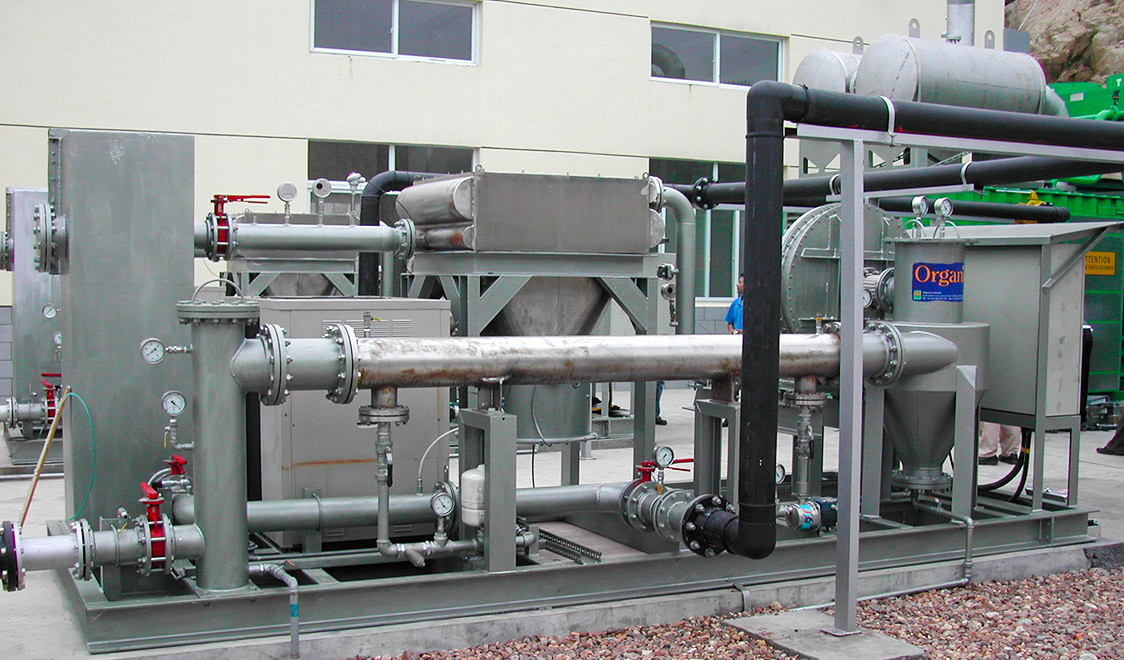

Biogas Generation, Indonesia

The system installed consisted of a covered lagoon biodigester complete with fuel delivery skid, biogas cleanup (removal of H2S) and supply to 2 No. biogas engines generating 2,100kW. The energy and heat produced were used on site in the process of producing tapioca.

Details of the Project

Project Type: Biogas produced from a CLAR to power generation

No. and model of flare stacks: 1 No. 1,000Nm3/h booseter set biogas delivery modules, 1 No. H2S cleanup system and 1 No. AC-range open flarestack for stand-by.

Year of installation: 2014

Availability of fuel skids: >90%

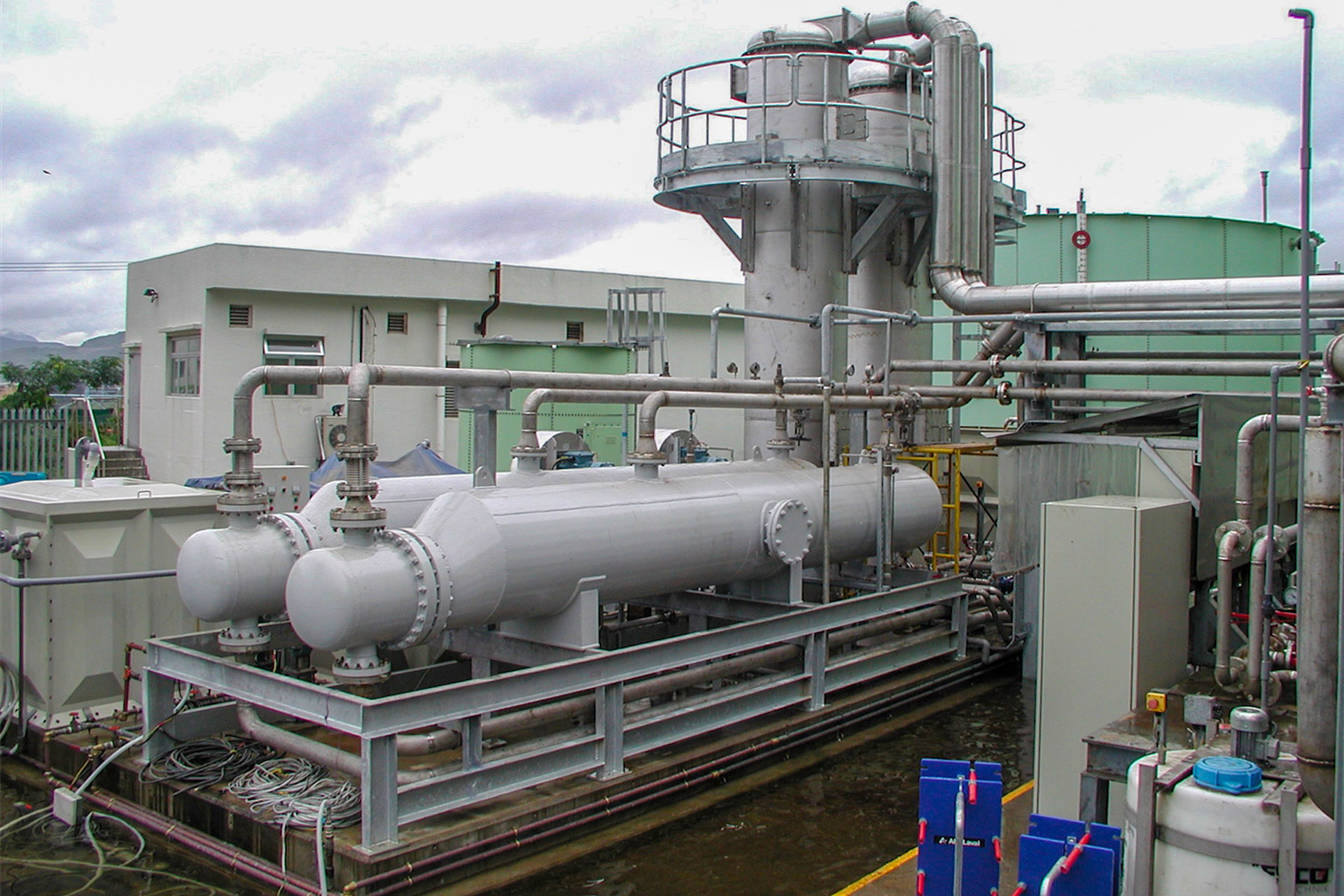

Electricity Generation, China

The system installed consisted of 2 No. 1,064kW engines fed by a landfill biogas extraction system. The biogas was delivered to the engines via a fuel skid and chiller system to ensure that the dew-point of the biogas was kept low enough to remove as many impurities as possible. The energy was used both on site for the waste management processes and excess energy was fed into the national grid.

Details of the Project

Project Type: Biogas from landfill to power generation

No. and model of flare stacks: 2 No. Jenbacher 1.064kW engines, 1 No. 1,000Nm3/h booseter set biogas delivery modules, 1 No. chilling system and 1 No. SC-range 1,000Nm3/h open flarestack for stand-by.

Year of installation: 2013

Availability of fuel skids: >90%

ORGANICS GROUP

Please consult the following pages before using our site:

Organics Privacy Policy

Data Privacy and Protection Policy

CONTACT

Please contact us for further information

SOCIAL MEDIA